OEM vs ODM: Which Manufacturing Model Fits Your Business Best?

When it comes to sourcing quality spare parts or tools — whether for motorcycle, bicycle, automotive or professional hand tools —businesses often come across two key manufacturing models: OEM and ODM.

While they may seem similar, understanding the difference can help you make smarter decisions, control costs, and get your products to market faster.

In this article, we’ll break down the basics of OEM and ODM, highlight the pros and cons, and explain how K-Star supports both approaches.

What Does OEM Mean?

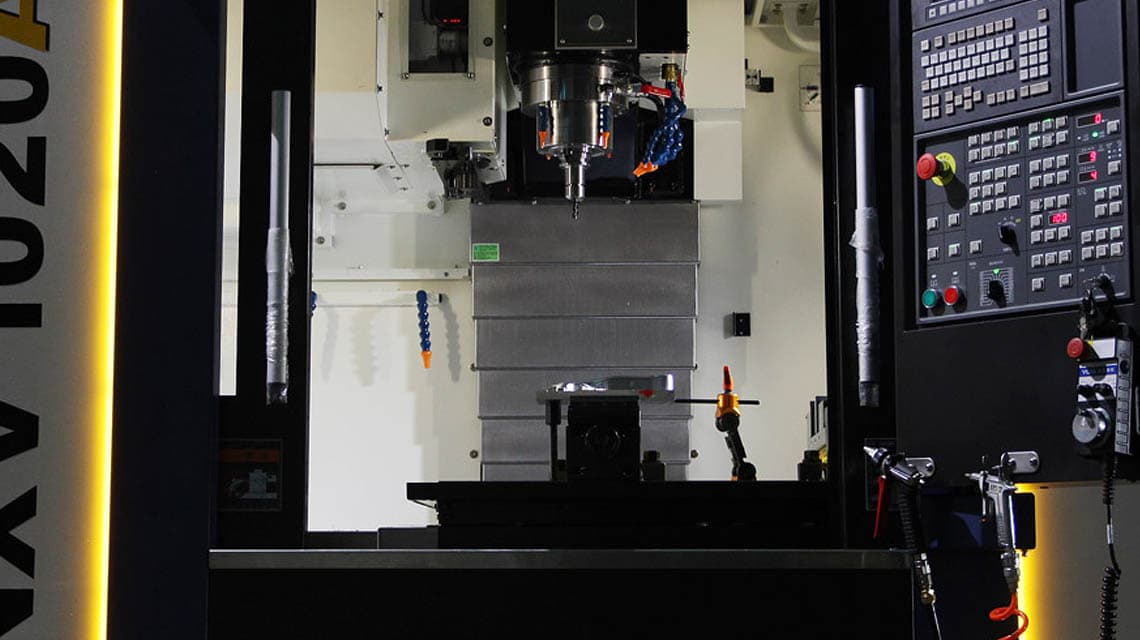

OEM stands for Original Equipment Manufacturer. In simple terms, this model is all about you providing the product design, and the manufacturer (like us) taking care of production.

How OEM Works:

-You (the client) provide the product design, drawings, or technical specs.

-K-Star manufactures the parts exactly to your specs — no shortcuts.

-You keep full control over branding, packaging, and marketing.

OEM is a great fit if you:

-Want a customized product tailored to your market.

-Have your own R&D or technical team.

-Need full control over design and brand.

What Does ODM Mean?

ODM stands for Original Design Manufacturer. This model is more flexible and often faster. The manufacturer provides a product that’s already designed and ready for you to brand and sell.

How ODM Works:

-K-Star provides pre-designed spare parts or tools.

-You choose the product and apply your own branding.

-It's quick, efficient, and cost-effective.

ODM is a smart option if you:

-Need to launch fast or test a new market.

-Don’t want to spend time or budget on product development.

-Are looking to expand your catalog with reliable products.

At K-Star, we support both OEM and ODM models, whether you need a custom spare part, a new line of branded tools, or want to scale fast, our team and factory network are ready to deliver.

Contact us today to turn your idea into reality.